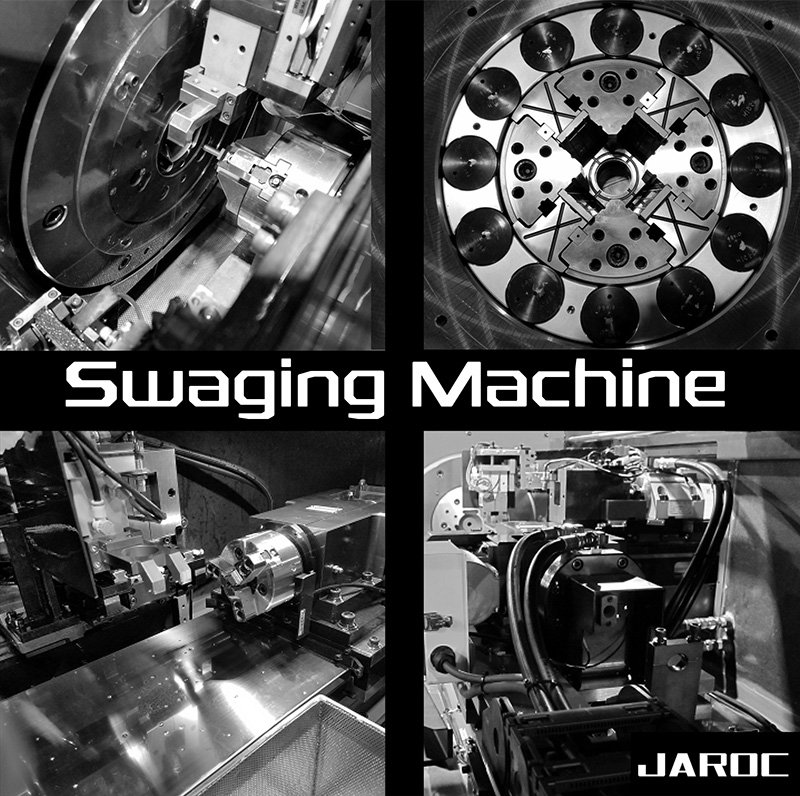

Machine Production

SW-8003

Processable wire diameter Φ1.0-Φ6.0

- It can supply coil materials directly.

- Die setup in case of material diameter change is easy.

- Long material and coiled Material can be supplied in combined.

- Difficulty processing materials such as NT alloy Can be processed.

The coil material sent by a reel stand is drawn with a built-in rotary straight line machine.

After swaging processing, clamp cut in certain dimensions.

Dedicated machine for coil material processing (Processing feed guide is equipped)

SW-8003N

There is also dedicated machine for center-less material such as NT alloy.

There is also supply device with material for 2M, 3M.

SW-20

SW-30

Stroke diameter 30mm

- Serration processing is possible.

SW-40

Processing Consignment Parts

Swaging parts

Titanium alloys such as pure titanium and β-titanium and non-ferrous metals such as copper and aluminum can be processed without cutting chips, which contributes to an improvement in yield rate. In addition, work hardening by cold forging improves the spring constant.

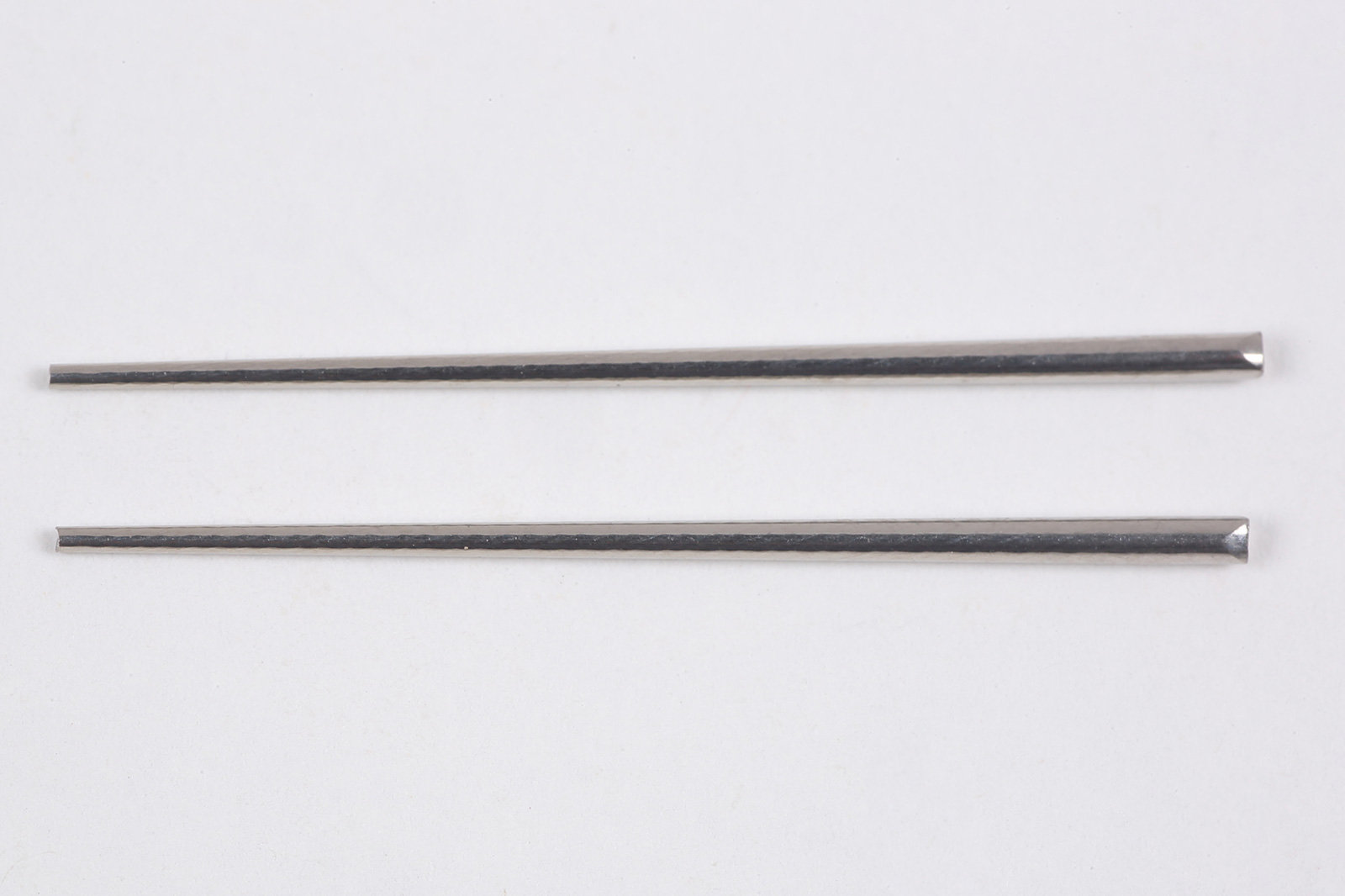

Small diameter swaging

Small diameter pipe

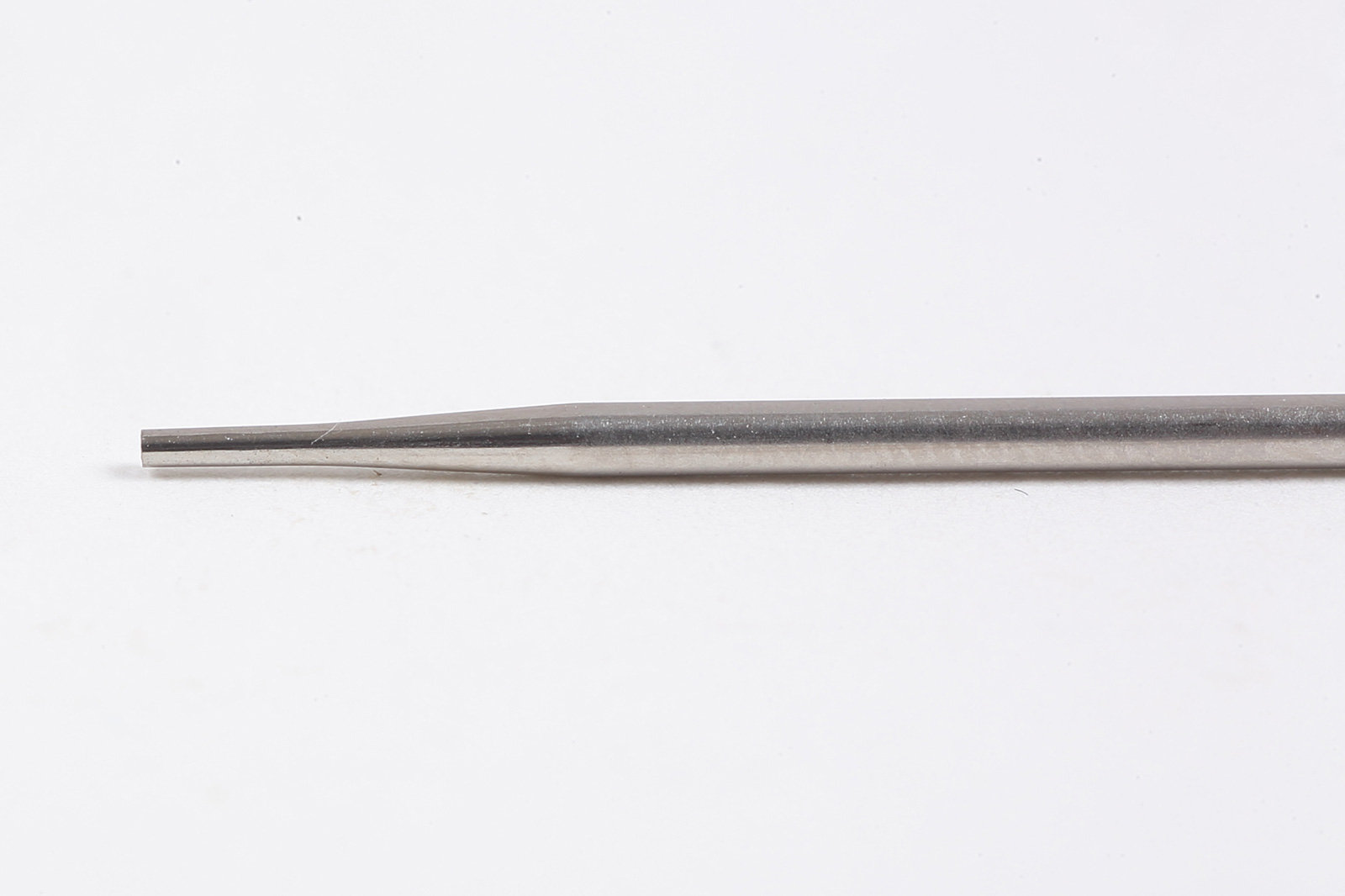

Long taper processing (suction tube)

Material: SUS304, titanium, aluminum, brass, etc. (pipe)

Application: Suction pipe, etc.

Raw pipe φ6 x 0.3t → φ2.5 x φ1.5 x 300L with taper

Please contact us for outer diameter, inner diameter, wall thickness and taper length.

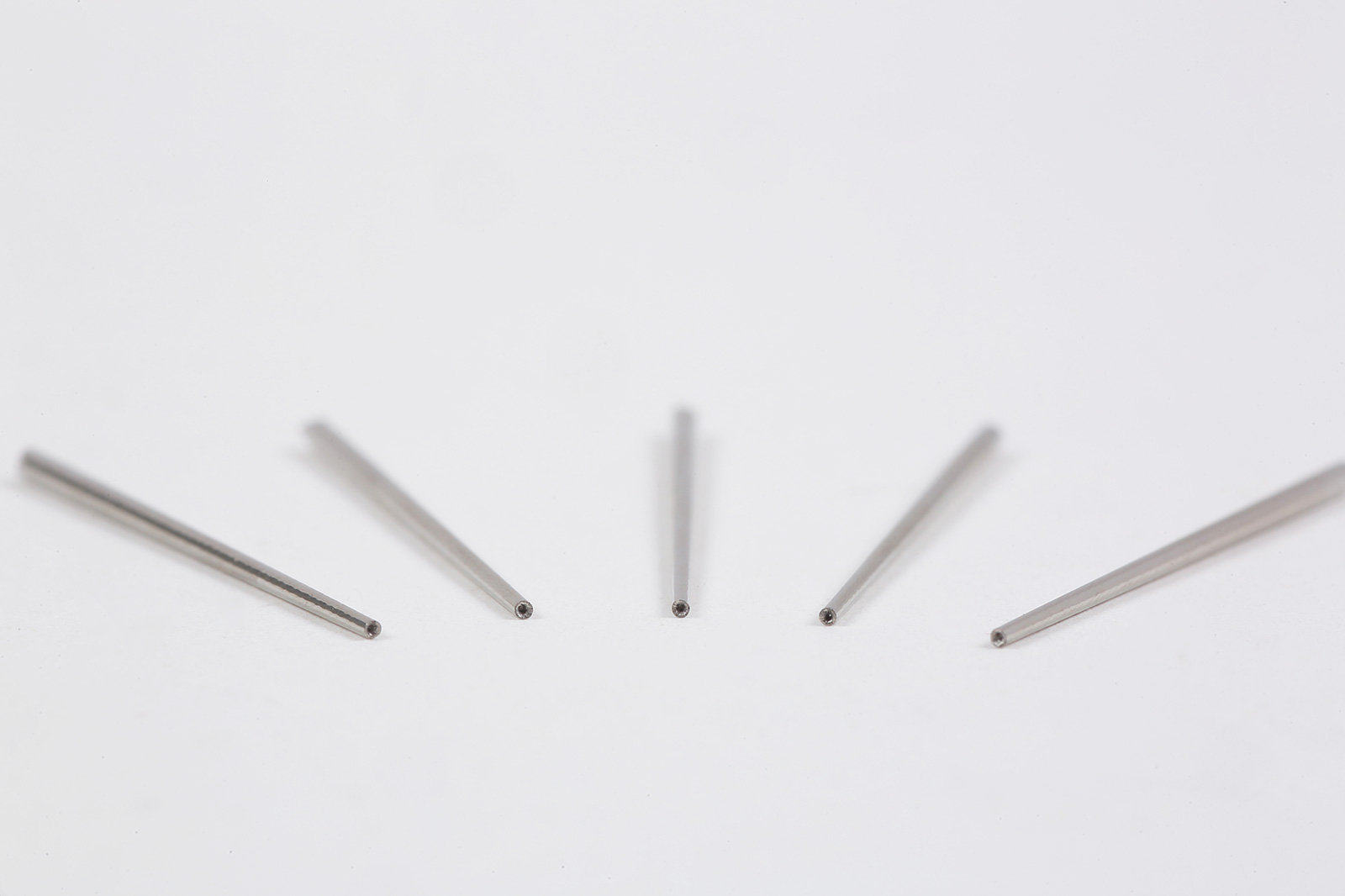

Stranded wire swaging process

Material diameter φ0.42 1 x 5 φ0.14 → Processed diameter φ0.37 L=3000

Processing possible for various types of twist: 1x7, 1x19, 7x7, 7x19, 1+5, hollow wire, etc.

and stranded wire materials: pure titanium (titanium wire), various titanium alloy, SUS304, Copper, etc.

with the wire diameter: φ0.2mm to φ2mm and the processing can be performed continuously from coil.

Torque performance and operability can be improved by improving tensile strength and reducing surface friction. Also ideal for medical wires.

Continuous line intermediate drawing processing

From the coiled material wound around the bobbin, diameter reduction processing (intermediate swaging) is performed to any shape, and products of the same shape are processed in a continuously connected state, and the processed shape is evaluated and guaranteed.

Material: Non-ferrous metal material (Ni-Ti material, titanium alloy material, SUS material, copper, plating material), etc.

Material Wire diameter: about φ0.3 mm ~ φ1 mm

Material: Non-ferrous metal material (Ni-Ti material, titanium alloy material, SUS material, copper, plating material), etc. Material Wire diameter: about φ0.3 mm ~ φ1 mm

By performing continuous processing (continuous line processing), it contributes to cost reduction in the subsequent process. The processing shape can also be changed as desired. Especially recommended when you want to process the tapered shape with high accuracy. Since the tensile strength per unit area of the processed part is improved, it is possible to control such as giving strength even if the diameter is small and supple.

Pressed parts

In addition to swaging parts processing, we also handle pressed parts processing.

Please feel free to contact us for processing availability and quotation.