What is swaging?

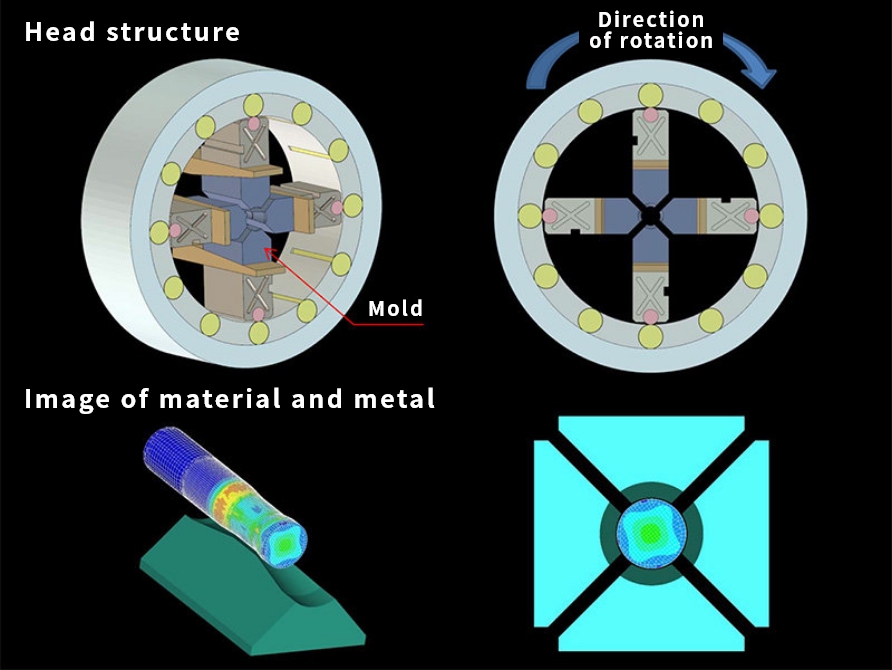

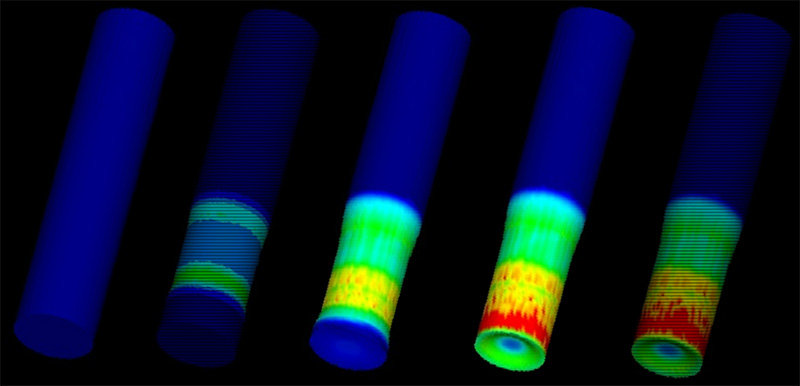

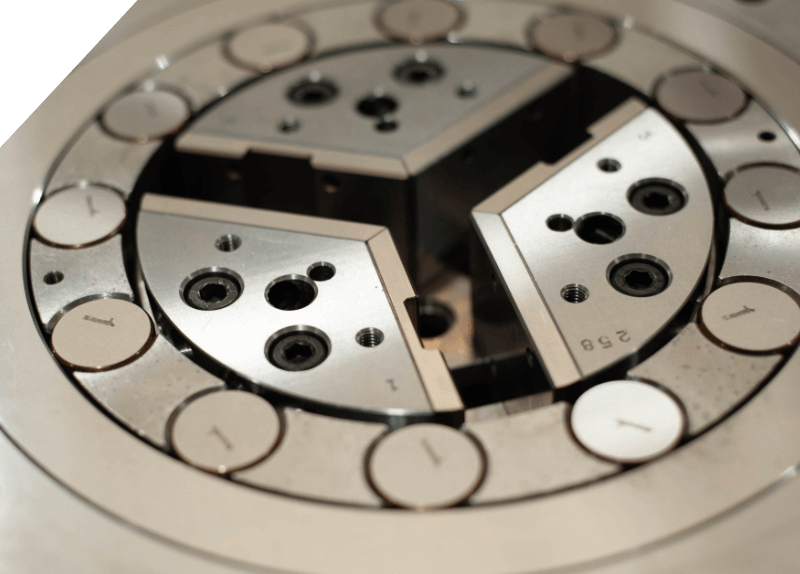

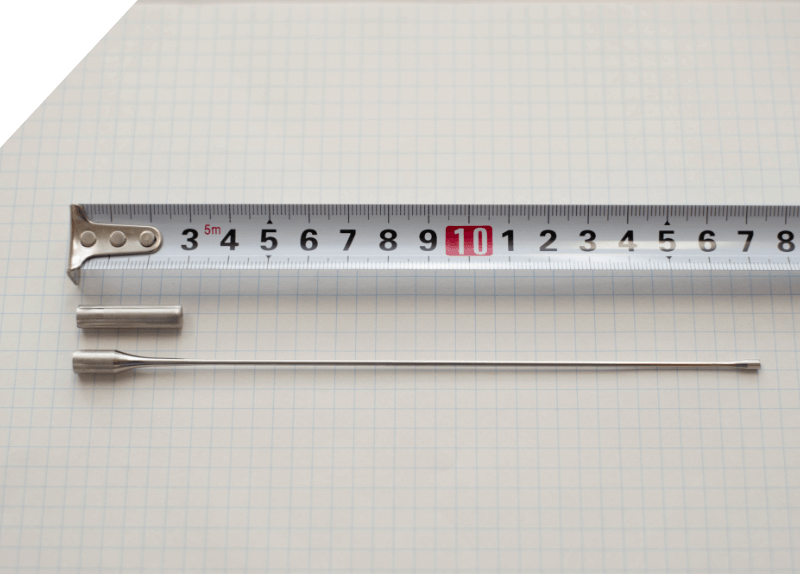

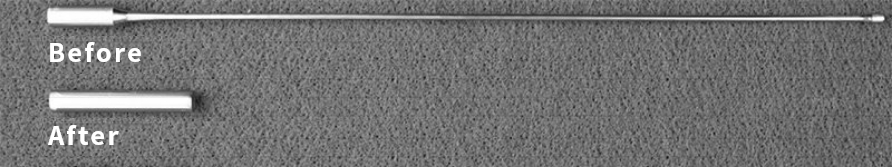

Swaging is cold forging process by plural dies which is rotating around the material pass line to reduce the outer diameter of the pipe and round bar.

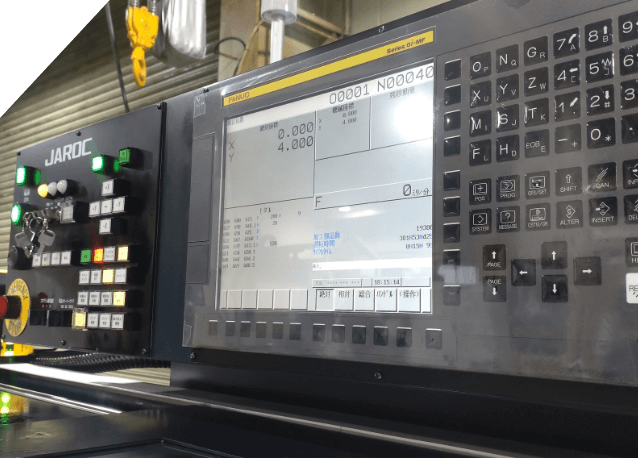

JAROC offers products with high dimensional accuracy by applying CNC (Computer Numerical Control) technology in which die setup and dimension adjustment is carried out quite easily. For the tube spline, it is possible to create a female-shaped spline shape to the inner diameter by swaging processing in the situation where cored bar of the spline (male type) is put in pipe.

In addition, there are other advantages such as there is no cutting chip, the product yield is improved, and the strength of parts is increased by work hardening. So, it is hoped that it spreads through various fields in future.

CNC swaging processing principle

It is a cold forging process in which the divided dies rotate and the outer diameter of the round bar or pipe material is reduced while tapping. CNC makes it easy to adjust in diameter and longitudinal direction, and enables highly accurate machining. It does not generate chips and has advantages such as reduction of material cost.

Merits of swaging processing

Because it is cold forged, it does not cut the material and is chip-free.

The inner diameter spline shape can be processed by inserting a core metal into the inner diameter processing. The inner wavy accuracy is also enhanced.

Machining with good dimensional accuracy is possible with CNC control.

We can also process Ti, Ti-6Al-4V, β-Ti, Ni-Ti, Al, Sus and Mg.

By molding conventional solid material products with hollow materials, we can reduce the weight of parts.

Material costs are reduced because the material is stretched from the shortest material.

What is plastic working?

Plastic working is to deform the material into the aimed shape by applying a mechanical force to the material, without dissolving and cutting. As for the metal materials, mechanical properties such as the strength are improved by performing plastic working process.

In addition, the plastic working is generally more advantageous than cutting regarding the cost, because there is little loss of materials, and processing speed is fast. It is used for the production of industrial products widely because processing time is shorter than other processing methods, and there is little loss of materials in general.

There are kinds of plastic working such as forging, press, rolling, extrusion, wire-drawing, bar-drawing, tube-drawing and reducing work, and thus plastid working occupies the important field of the metal working process.